HS2 TBM Dorothy completes second drive underneath Long Itchington Wood

This post was originally published on this site

High Speed 2 (HS2) main works contractor BBV (Balfour Beatty Vinci) has completed its second drive with tunnel boring machine (TBM) Dorothy below Long Itchington Wood, Warwickshire.

The TBM – named after Nobel Prize winning chemist Dorothy Hodgkin – was launched in November last year to bore the second 1.6km Long Itchington tunnel for the high-speed rail project.

This breakthrough is the second for HS2, BBV and TBM Dorothy and the first twin-bore tunnel completion on the project.

The completion of the second tunnel was slated for summer of this year meaning TBM Dorothy has finished its journey slightly quicker than expected, in just four months.

Rail minister Huw Merriman said: “This is yet another ground-breaking moment in the delivery of HS2 and the transformation of journeys and communities across Britain.

“With the help of TBM Dorothy, these tunnels are paving the way for HS2 trains while preserving ancient woodland on the land above. These tunnels help ensure that we deliver this transformative project while protecting the natural environment.”

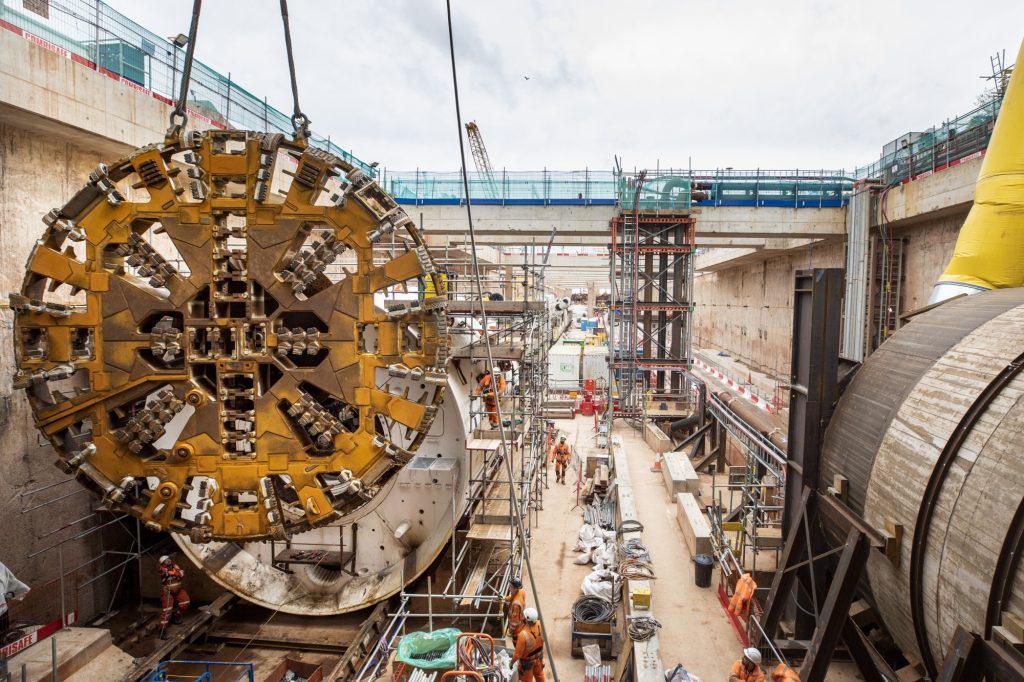

Members of the BBV tunnelling team were on site to witness the moment the 10m diameter cutterhead broke through the reception box headwall. This marks the culmination of a three-year operation, from site set-up and TBM assembly, the first TBM drive and breakthrough, and now completing the second breakthrough.

TBM Dorothy has put 791 concrete rings to form the primary tunnel lining in place, with each ring made from eight 2m-wide segments that each weigh up to 8t.

Over the next few weeks, work will begin to dismantle the shield from the TBM, while the rest of the machine will be pulled back to the start of the tunnel and disassembled, ready for transportation to the east of Birmingham. There, the TBM will be fitted with a new shield so that it can begin a 5.6km tunnel bore in early 2024, between Water Orton in Warwickshire and Washwood Heath in Birmingham.

HS2 delivery director for main works civils on phase one David Speight said: “I’d like to congratulate the 400-strong BBV tunnelling team for achieving this fantastic milestone on the HS2 project.

“We’re looking forward to celebrating more milestones as work gathers pace on key structures such as the Delta Junction viaducts, Birmingham Curzon Street station, Interchange station and Washwood Heath Depot, creating more opportunities for local businesses and people.”

TBM Dorothy was launched for the first tunnel in December 2021 and then produced the first HS2 tunnel breakthrough when it completed its 1.6km drive beneath the ancient woodland in July last year. With its relaunch, it also became the first of HS2’s TBMs to be reused for a second drive.

In order to get TBM Dorothy ready for its second drive, the TBM’s gantries – which each weigh over 1,000t – were transported back through the tunnel and reassembled at the north portal. The 160t, 10m-wide cutter head was transported via road in an intricate operation that took place in September 2022.

Balfour Beatty HS2 major projects CEO Michael Dyke said: “Successfully completing the first twin-bore tunnel on Britain’s new, highspeed railway is yet another demonstration of how works continue to progress at pace across the project. It’s a huge achievement, not only for BBV, but for everyone connected with HS2.

“Watching Dorothy break through her second one-mile journey today was only possible thanks to months of hard work and dedication from our 400-strong project team, who deserve a special mention for safely delivering this incredible feat of engineering.”

The woodland is a Site of Special Scientific Interest (SSSI) with complex ecosystems that have been established over the course of centuries, and HS2 took special precautions to ensure it managed the environmental impacts during the construction of the tunnel and railway.

Excavation from the two drives of the twin bore tunnel produced around 500,000t of mudstone and soil. This was processed at an on-site slurry treatment plant before being separated and transported via a 254m conveyor to be reused in the formation of embankments along the route of the railway.

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.

Responses