Timber Frame External Wall Construction Details UK: A Comprehensive Guide

This post was originally published on this site

As the popularity of timber frame construction continues to rise in the UK, understanding the intricacies of timber frame external wall construction details UK becomes increasingly important. Whether you’re a self-builder, an architect, or a homeowner, this comprehensive guide will walk you through the essentials of timber frame walls, insulation options, vapour control layers, and more. Stay with us as we unravel the complexities of this eco-friendly and energy-efficient construction method.

Short Summary

- Understand the theory of timber frame external wall construction, including studs and sheathing, ventilation membranes and cladding.

- Utilize breathable insulation materials to improve thermal performance, air quality and reduce energy costs.

- Ensure structural elements like wall ties are installed correctly with a reputable supplier for long term performance.

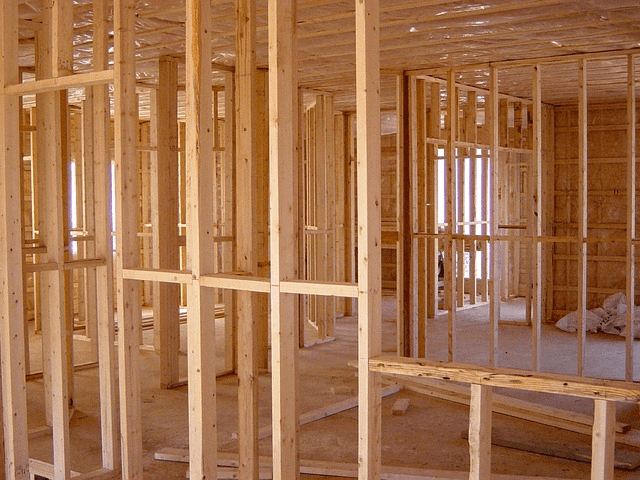

Understanding Timber Frame External Walls

Timber frame external walls are composed of structural studs that bear the imposed loads before transferring them to the foundations. It is essential to comprehend the theory of detailing for timber frame external walls to adhere to the specification list and ensure the wall’s construction. One of the advantages of insulated external timber frame walls is their improved insulation performance compared to masonry walls of similar thickness and low embodied energy.

An external breathable membrane is laid over a layer of structural sheathing, followed by a primary layer of insulation to fill the voids between the structural studs. The panel studs are then insulated with a secondary layer of insulation. This is then covered by an air-tight vapour control barrier. These layers play a crucial role in controlling moisture and air movement within the wall system, protecting the insulation and timber frame structure.

Studs and Sheathing

Timber frame studs are vertical wooden framing members that form part of a wall or partition in a timber frame wall system, providing support for the sheathing and extending from the foundation plate to the rafter plate, spanning the full height of the building. They can be constructed from a range of materials, such as softwood, hardwood, engineered wood, and metal, with softwood studs being the most commonly used in residential construction.

Plywood is the most common sheathing material used in timber frame walls for residential construction, while oriented strand board (OSB) is a more cost-effective option often used in commercial construction. Properly installed sheathing ensures the stability and integrity of the timber frame structure.

Breather Membranes

Breather membranes are water-resistant yet vapor-permeable materials, commonly utilized in external walls and roofs to enable water vapor to escape from inside a building while preventing moisture from entering the structure. The external breathable membrane plays a vital role in regulating moisture and air movement within the timber frame wall system, preserving a healthy and comfortable indoor atmosphere.

By managing moisture effectively, breather membranes contribute to the longevity and performance of the timber frame structure.

External Cladding

External cladding comes in a variety of materials, such as wood, metal, brick, stone, vinyl, and composite materials, each offering unique characteristics and advantages. Besides enhancing the aesthetics of the building, external cladding can improve the thermal performance of the wall, limit air leakage, and protect the wall from moisture and other external elements.

Choosing the appropriate cladding material and proper installation can significantly impact the timber frame wall system’s overall performance and longevity.

Insulation Options for Timber Frame Walls

Common insulation options for timber frame walls include fiberglass batts, mineral wool batts, and rigid foam boards, with mineral wool being the preferred choice due to its superior thermal, fire safety, and acoustic performance. The thermal performance of insulation options varies, with mineral wool batts offering the best performance among the alternatives.

Breathability is also an essential factor to consider, as mineral wool batts are highly breathable, while fiberglass batts are not. The environmental impact of insulation materials should not be overlooked, as fiberglass batts have a higher impact than mineral wool batts, while polyisocyanurate (PIR) board and glass mineral wool (GWM) have a lower impact.

Breathable Insulation Materials

Breathable insulation materials, such as flexible wood fibre batts, wool, and hemp, are vital to maintaining the desired temperature and preventing condensation within timber frame walls. Utilizing breathable insulation materials offers a range of advantages, including enhanced thermal performance, improved air quality, reduced condensation, and decreased energy costs, ultimately enhancing the overall comfort of a dwelling.

By opting for breathable insulation materials, homeowners can ensure the long-term performance and efficiency of their timber frame structure.

Third-Party Certification

Third-party certification is a process where an independent organization assesses and verifies that a product or service adheres to established standards or requirements, providing confidence in compliance and assurance to stakeholders.

Selecting insulation products with third-party certification, such as BBA (British Board of Agrément), CE (Conformité Européenne), and ISO (International Organization for Standardization), is essential to guarantee that insulation products adhere to the required standards and regulations, as well as to minimize risks by recognizing any non-conformities.

It is a crucial step in ensuring the quality and performance of the insulation materials used in your timber frame project.

Installing Insulation in Timber Frame Walls

The most common method for insulating timber frame walls is using a foil-faced foam board or a glass/mineral wool, often combined with a foil blanket to enhance the U-values. The insulation should be placed between the timber studs, and a vapor barrier should be installed to cover it.

It is recommended to wait until the timber frame reaches a humidity content lower than 20%. Additionally, the building should be weather tight before installing insulation.

Moisture Control

Moisture control is crucial in timber frame external wall construction, as it ensures that the timber is at an optimal moisture content before installing insulation, thereby protecting the timber frame structure from potential damage caused by excessive moisture.

Managing moisture in timber frame external wall construction involves the use of breathable membranes, vapour control layers, and permeable membranes, which effectively prevent moisture from entering the timber frame and reduce the amount of moisture retained within the timber frame.

Filling Voids

Flexibility, airtightness, and complete filling of voids are essential when installing insulation in timber frame walls. A combination of flexible sealant and flexible polyurethane foam can be used to fill the gaps in timber frame walls.

It is essential to make sure that the space behind noggins or boards installed between studs to support services or heavy fittings is completely insulated. Failing to do so can cause damage or disruption to the services and fixtures. Properly filling voids in timber frame walls maximizes insulation effectiveness and prevents moisture infiltration.

Closed Panel Considerations

Closed panel systems, which come with insulation pre-installed in the factory, require additional considerations to ensure that the insulation is correctly sealed and that any moisture entering the wall cavity can escape. When working with closed panel systems, accuracy and levelness of the foundations are essential for proper support of the panels, and the panels’ weight requires using a crane for assembly.

By carefully considering these factors, homeowners can ensure the proper installation and performance of closed panel timber frame systems.

Vapour Control Layers and Condensation Management

Vapour control layers play a key role in managing condensation risks and maintaining the integrity of the timber frame structure by minimizing the possibility of condensation forming within the timber frame and safeguarding the integrity of the wall system. To achieve the desired insulation performance, it is essential to install a vapour control layer on the warm side of the insulation, with a vapour resistance ratio of at least 5:1 between the materials on the warm and cold side of the insulation.

Vapour Control Layer Installation

To install a vapour control layer in a timber frame wall, it is necessary to cover the external framed wall area, including rails, studs, reveals, lintels, and sills. The VCL should be securely fixed at 250mm centres to the top and bottom of the frame, at laps, and around openings.

Installing the VCL in accordance with the manufacturer’s instructions and ensuring proper wall construction, cavity size, and insulation type will help prevent moisture penetration of the timber frame wall and potential damp and mould issues.

Permeable Membranes

Permeable membranes, such as polyethylene, polypropylene, and polyurethane, are effective in reducing air infiltration, enhancing air quality, and minimizing the risk of condensation. They can also aid in reducing energy costs by providing an additional layer of insulation.

When used in conjunction with vapour control layers, permeable membranes offer a comprehensive solution to manage condensation and moisture in timber frame walls, ensuring the long-term performance and durability of the timber frame structure.

Timber Frame Wall Systems: Open vs Closed Panels

Open and closed panel timber frame wall systems differ mainly in their approach to insulation. Open panels are supplied to the site without insulation, while closed panels come with insulation pre-installed in the factory.

Closed panels are frequently provided by German turnkey home suppliers and can facilitate a rapid construction. Both systems have their advantages, and the choice between them depends on the specific requirements and preferences of the homeowner or builder.

Open Panel Systems

Open panel systems feature an open panel design, providing increased flexibility in construction, as well as improved air circulation and insulation. The components of an open panel system generally include a network of wooden studs and sheathing.

The open panel system offers improved air circulation, better insulation, and increased flexibility when constructing the wall, making it a popular choice for many timber frame projects.

Closed Panel Systems

Closed panel systems are pre-manufactured, partially-finished panels, such as load bearing wall elements, roof trusses, floor structures, and internal studwork. These systems offer enhanced thermal performance, increased structural stability, and expedited construction time.

The factory production of these panels ensures precision engineering and adherence to performance standards, making closed panel systems a reliable choice for those seeking faster construction and superior insulation performance.

Structural Elements and Connections in Timber Frame Walls

Timber frame walls incorporate components such as wall ties, roof trusses, and cavity barriers to join the various components of the wall together, providing stability and strength.

Understanding these structural elements and connections is crucial to ensuring the proper construction and performance of timber frame walls.

Wall Ties

Wall ties are connectors used to join the two leaves of a cavity wall, such as a timber frame wall, together, allowing the two parts to act as one unit and ensuring the stability of the building. Wall ties must be corrosion-resistant and able to accommodate the applicable loads, as well as any movement between the inner and outer walls.

Proper installation and distribution of wall ties in a staggered pattern are essential to maintaining the integrity of the timber frame structure.

Roof Trusses

Roof trusses are structural frames utilized to support the roof of a building, generally constructed from timber, and designed to transfer the load of the roof to the walls of the building. They play a vital role in the overall stability and performance of timber frame structures and must be properly integrated and secured in the timber frame wall system.

The trusses must be designed to meet the specific requirements of the building, taking into account the size, shape, and load of the roof, as well as the type of timber used. The trusses must also be securely connected to the walls of the building.

Cavity Barriers

Cavity barriers are employed in timber frame construction to impede the propagation of fire through the cavity while concurrently permitting the building to breathe. They are usually installed in proximity to the edges of internal cavities and at junctions where the wall cavity is aligned with a building compartment wall or floor.

Cavity barriers not only play a crucial role in fire protection, but they also assist in moisture management within timber frame walls, further ensuring the long-term performance and durability of the timber frame structure.

Choosing a Timber Frame Supplier

Selecting a reputable timber frame supplier for your project is essential to ensuring the quality and performance of your timber frame structure. When evaluating quotations and small print, be sure to note what is and is not included. Utilizing pre-manufactured panels in timber frame construction provides the certification required to meet Building Regulation requirements and guarantees satisfaction for your warranty provider.

Look for suppliers with third-party certifications, such as ISO (International Organization for Standardization), BBA (British Board of Agrément), or CE (Conformité Européenne), to ensure compliance with established standards and requirements. Don’t forget to research customer reviews and testimonials to gain insights into the supplier’s track record and overall reputation in the industry.

By carefully considering these factors, you can confidently select a timber frame supplier that will meet your project’s needs and expectations.

Summary

In conclusion, understanding timber frame external wall construction details is vital for anyone involved in a timber frame project. From the various components and materials used in timber frame walls to insulation options, vapour control layers, and structural elements, this comprehensive guide has provided you with the knowledge necessary to make informed decisions about your timber frame project. Armed with this information, you can now confidently choose a reputable timber frame supplier, select the right insulation materials, and ensure the proper installation and performance of your timber frame structure. Embrace the benefits of timber frame construction and embark on a more sustainable, energy-efficient building journey.

Frequently Asked Questions

How thick should an external timber wall be?

For an external timber wall, the most commonly recommended thickness is 70mm. This thickness ensures adequate thermal and acoustic performance while providing enough stability for outdoor use.

How are timber framed walls constructed?

Timber frame walls are typically constructed from pre-manufactured frames filled with insulation and stiffened with OSB panels, consisting of hardwood studs and braces nailed with simple butt joints to top and base plates.

The outer wall surface is usually clad with sheet material, such as plywood, which is then screwed or nailed to the stud work.

How thick is an external timber stud wall?

A timber stud wall typically ranges in thickness between 50mm and 90mm, depending on the desired thermal and acoustic performance.

What goes on the outside of a timber frame house?

The outer surface of a timber frame house is typically clad with protective material to ensure the longevity of the structure. Popular options for cladding include brick or block, cement fibreboard, stone, metal and timber, each offering unique advantages in terms of protection, insulation, aesthetics and budget.

Ultimately, careful consideration should be made when selecting a cladding material for a timber frame home.

Responses