TEC: One stop storage

This post was originally published on this site

TEC Container Solutions’ all-in-one storage system has emerged as a preferred method of bitumen storage for many major infrastructure providers across the country.

Truly national coverage and supply is the aspiration of many across the construction materials sector. Catering for both regional and metro projects can present a number of challenges, but one of the biggest has always been transport and storage.

For as essential of a component as it is, bitumen has previously been logistically challenging, with transport being just one aspect. Having a product that’s ready to go and in the right window is another.

That’s why TEC Container Solutions set out to find a permanent cure for this frequent headache.

Founded in the 1990s, TEC Container Solutions was formed for one reason; to provide safer and smarter alternatives to single skinned bitumen/asphalt containers, while also delivering a solution that doesn’t require heat maintenance.

This was no easy feat, with years of development and research committed to provide a unit that could benefit the

industry as a whole.

Best investment into this development has led to the creation and success of the products that TEC is renowned for across the globe.

It’s this success that has led to TEC working with major construction companies such as Colas, Downer, Fulton Hogan etc., who have been proud users of TEC’s solutions over the years.

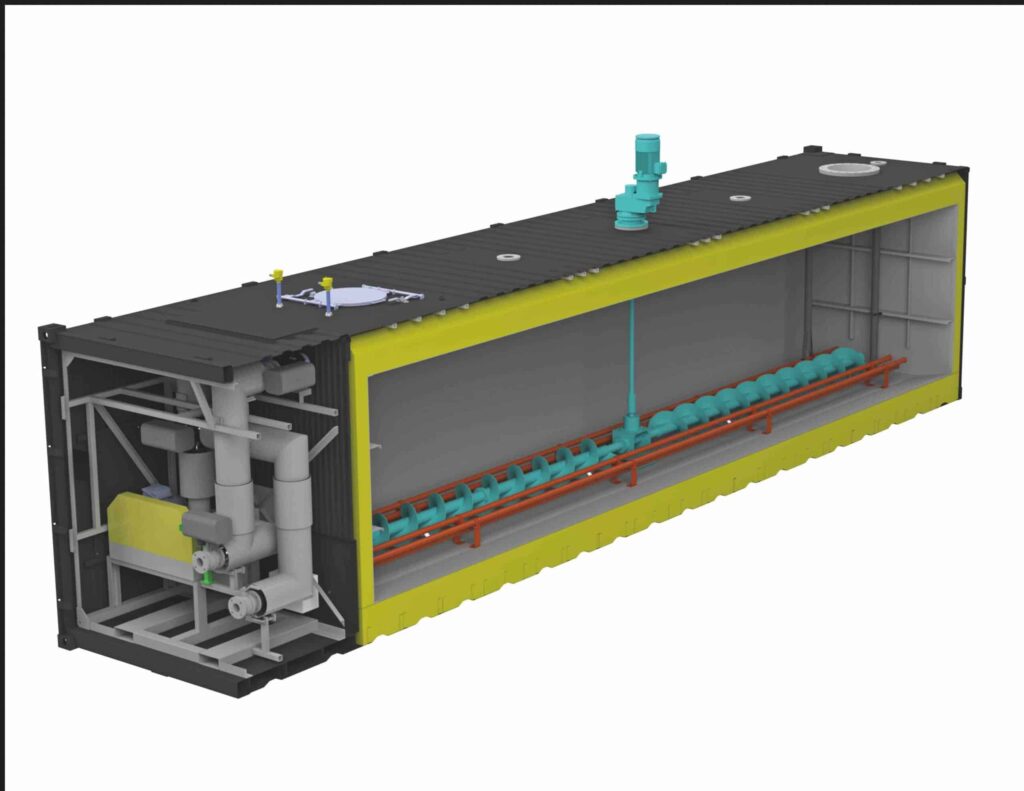

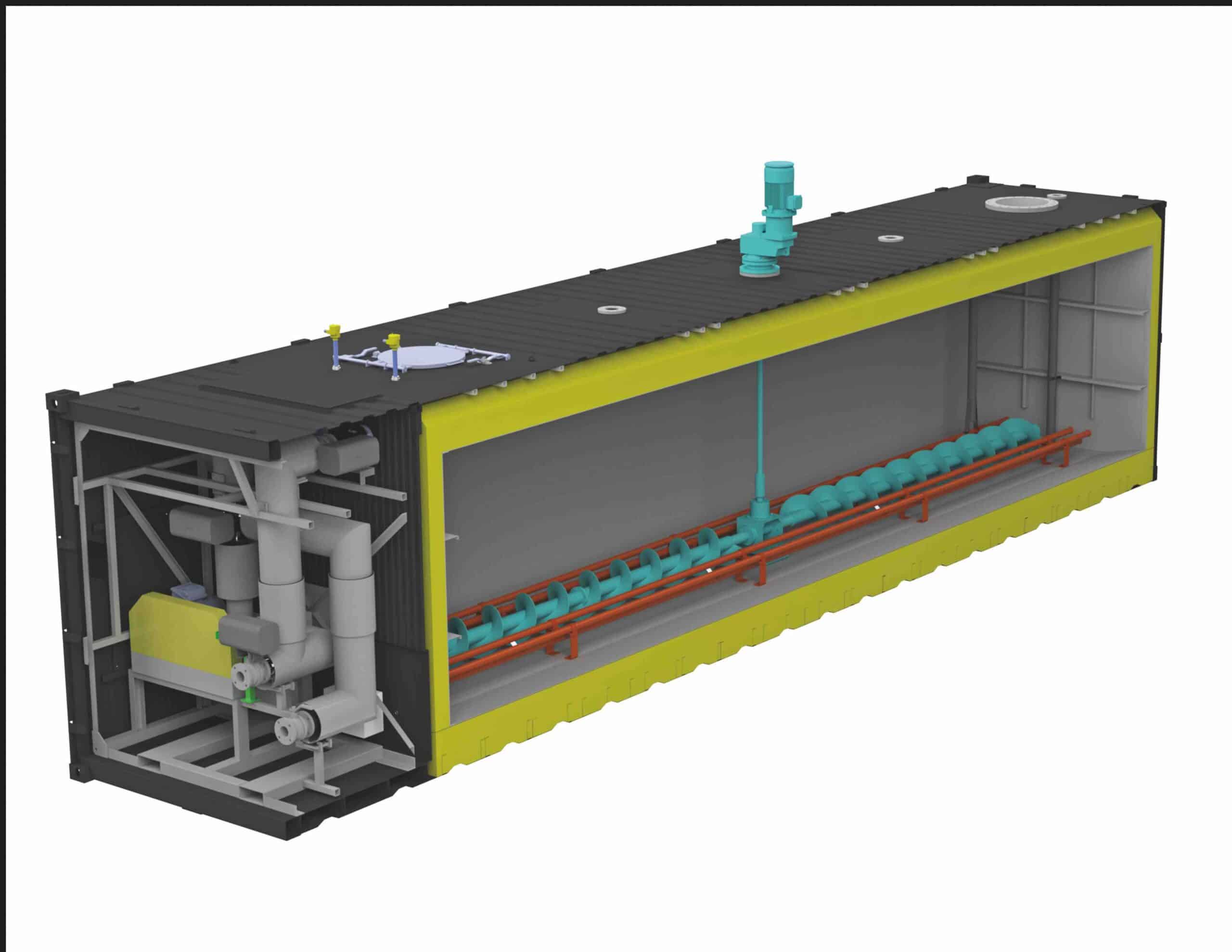

TEC’s newest addition to the Bitutainer™ Storage range – the MEST Bitutainer™ – is the culmination of years of experience designing tanks, as well as thousands of hours’ worth of engineering and industry expertise.

What’s inside?

The MEST Bitutainer™ is a 40ft self-contained bitumen storage container that simplifies the handling, storage, and transportation of bitumen. The unit has been tailored to improve the efficiency and safety of bitumen transport and storage, particularly for speciality bitumen’s, such as emulsions, PMB’s and crumb rubber.

Able to fill, discharge and recirculate product via the built-in pipework manifold system, the MEST Bitutainer’s™ advanced control system is equipped with state-of-the-art monitoring and control technology to ensure safe optimal operation conditions are maintained.

Related stories:

Such technology is crucial to satisfy compliance with the rigorous AS Standards of both Australia and New Zealand.

The addition of a bottom mounted agitation system is ideally suited for use with crumb rubber, ensuring that rubber particles remain evenly distributed to maintain the optimal properties of modified bitumen. TEC’s design also ensures a well-insulated interior, featuring an efficient electric element heating system for lowering operation costs associated with bitumen storage.

Safety is always an important consideration, which is why users can have peace of mind. TEC’s MEST Bitutainerr™ features a secondary containment wall, which surpasses traditional safety requirements, avoiding the need for additional costly walls.

Building blocks

One of the best features of the MEST Bitutainer™ is its versatility to be used as part of an isolated, or major construction/infrastructure operation, due to the scalable and transportable nature of the system.

TEC has also designed its very own Bitumen Storage Facility, made specifically for bulk bitumen storage, often directly from vessels. Flexible, relocatable and scalable, the MEST Bitutainer™ and TEC’s Storage Facility work hand in hand for a comprehensive storage and distribution system that enhances operational efficiency.

The efficiency gains experienced from streamlining operations come about thanks to reduced product handling times and minimised logistical bottlenecks, both of which are prevalent with small capacity transport trucks.

This can also be used to support larger applications of materials such as crumb rubber and other forms of modified bitumen, helping to optimise the sustainable outcomes for a construction operation. All the while, having a quality, ready-to-go supply within close proximity to the construction site.

Savings on cost, time and material wastage are just some of the biggest benefits, combined with the customisation capabilities, allowing operations of all sizes to find an ideal solution for their needs.

This is also backed by TEC Container Solutions’ extensive technical support and expert advice, making sure that the MEST Bitutainer™ can fit seamlessly into an existing operation.

Jon Whittall, Managing Director at TEC Container Solutions commends the introduction of the MEST Bitutainer™ in the Australian and New Zealand markets.

“The MEST Bitutainer™ represents a significant leap forward in road construction logistics,” he says. “We designed this innovative solution to specifically tackle the inefficiencies and bottlenecks associated with traditional bitumen storage and transport, particularly for projects involving speciality bitumens. The MEST integrates seamlessly with our Bitutainer™ Storage Facility, offering a flexible and scalable system that adjusts to the evolving needs of our clients. By focusing on operational efficiency, safety, and compliance, the MEST Bitutainer™ empowers construction companies to streamline their bitumen logistics and deliver projects with greater precision and speed.”

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

This article was originally published in the June edition of our magazine. To read the magazine, click here.

Responses