Hinkley Point C | Unit 2 pools accelerated with welding technique and heavy lift cranes return

This post was originally published on this site

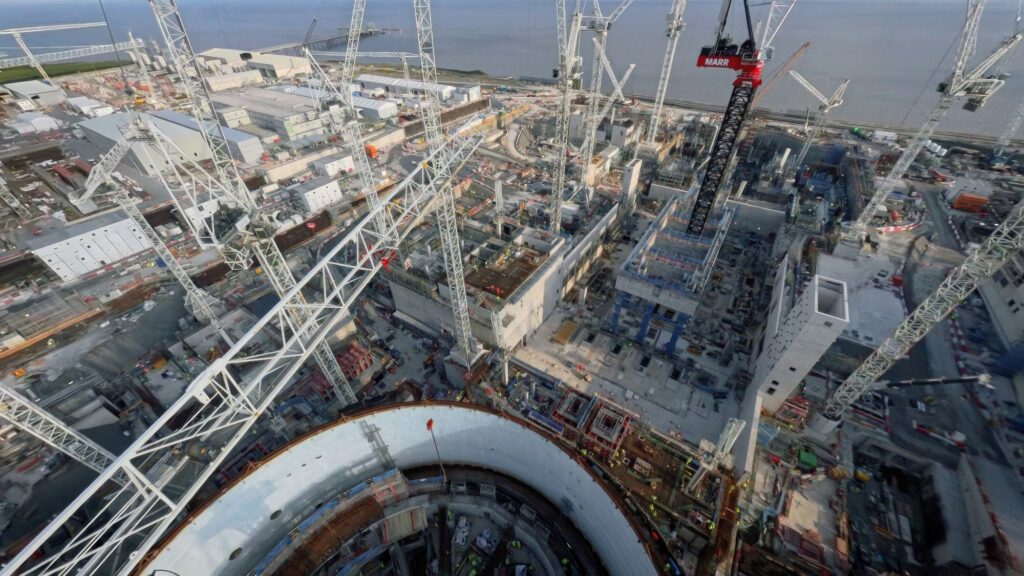

Synergic metal active gas (Smag) welding is being used at Hinkley Point C’s Unit 2 reactor to increase construction efficiencies, while the world’s largest tower cranes have returned to the site as construction ramps up.

Hinkley Point C nuclear island director Simon Parsons said in a video released by the nuclear power company: “We are typically building Unit 2 20 to 30% faster. It’s the same job, but we’re learning better ways to do it.”

One of those more efficient practices is using Smag welding for the pools in Unit 2.

Engineers decided to test this approach as they found that Unit 1’s pool panels got too hot during welding, which led to distortion and meant re-working was needed.

Additionally, teams needed to work in sequences to allow panels enough time to cool before building up the weld.

Hinkley Point C said that “this was inefficient, especially when welding at height, as it required teams to frequently change position and amend scaffolding for access.

“On Unit 2, a different welding technique (Smag) was proved to meet stringent nuclear standards without causing the same heat and distortion issue.”

Use of Smag has seen welding for the pools in Unit 2 being completed four times faster than those in Unit 1, “with minimal distortion and weld defects”, according to those working on the project.

A Hinkley Point C spokesperson indicated that the Smag welding technique itself is not new, but it has never been used in this type of nuclear application.

They also highlighted that the team behind the build had to work with the designer and regulator to make sure everyone was satisfied with the innovation.

An Office for Nuclear Regulation spokesperson (ONR) said: “We take an enabling approach when supporting new methodologies proposed by dutyholders.

“We are working alongside Hinkley Point C at each stage of development to ensure that the arrangements they propose are robust, and that all aspects of design and construction are carried out to the highest safety standards and meet our regulatory requirements.”

Marr Contracting return world’s largest tower cranes

Australian firm Marr Contracting was warded the lifting contract by Hinkley Point C main works contractor Bouygues Travaux Publics and Laing O’Rourke (Bylor) joint venture. Bylor was awarded the contract for main civil engineering and construction works by EDF in 2017.

The crane company will provide specialised heavy-lifting crane services for the construction of Hinkley Point C’s Unit 2 Turbine Hall.

Marr Contracting said in a statement: “Addressing the primary challenge of how to accelerate construction on what is an incredibly complex and congested site, Marr’s unique and simple approach – using a single M2480D heavy lift luffing crane installed centrally within the Unit 2 Turbine Hall – provides the heavy lifting capacity, reach and coverage required while at the same time improving productivity and reducing site congestion.

“With the ability to lift in main trusses weighing up to 122t and the ability to reach all building steelwork from a single position, the simplified craneage solution reduced interfaces with the wider project and the need for multi-location rig and de-rigging activities that would have been required using alternative methods.”

The company said its M2480D crane provides “the flexibility to operate as a high-volume general construction crane while also lifting in 70t pre-cast components as part of a varied cycle of operations”.

It also said its crane can operate in wind speeds of up to 20m/s which makes it suitable for Hinkley Point C’s coastal location.

The crane was installed in early April 2024 and is expected to be onsite until 2026.

Marr Contracting general manager – international Steve Ryder said: “It’s great to be returning to Hinkley Point C with a craneage solution that has significantly reduced complexity and will allow the focus to shift off the crane to productivity on the project.”

Hinkley Point C project manager David Wylie said: “Putting the M2480D inside the building means there’s far less disruption to other teams in the vicinity.

“We previously had to work around the movements of the crawler cranes and during a series of workshops, we identified this solution as one of the biggest things we could improve on, learning from our experiences on Unit 1.”

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.

Responses