Renfrew Bridge’s complexity poses challenges to designers and contractors

This post was originally published on this site

Even after modifications to meet the budget, the design of the Renfrew Bridge was one of the most challenging ever for its designers.

“I have been designing movable bridges for 42 years. This is the most complex structure that I have worked on.”

Hardesty and Hanover (H&H) bridge practice lead Jim Phillips is talking about the Renfrew Bridge, which Graham is building for Renfrewshire Council. The 184m twin-leaf swing bridge will span the River Clyde in Scotland between Lobnitz Dock in Renfrew to the south and Yoker to the north.

It is part of Renfrewshire Council’s £117M Clyde Waterfront and Renfrew Riverside project, funded from the £1.13bn Glasgow City Region City Deal.

“The location was chosen to maximise the connectivity benefits for the city region with the project covering Renfrewshire, West Dunbartonshire and Glasgow local authority areas,” says Renfrewshire Council’s programme director (City Deal and Infrastructure) Barbara Walker.

Anyone who needs to cross the Clyde from Yoker to Renfrew must travel to the Erskine Bridge or the Clyde Tunnel, or use the privately operated Renfrew Ferry, a pedestrian-only service.

The new bridge will provide a direct link for car users, cyclists and pedestrians, reducing travel times, while allowing commercial and leisure ships to travel down the river when it is open.

People living in Yoker, and beyond, will have easy access to the developing Advanced Manufacturing Innovation District Scotland (AMIDS) and the Braehead Shopping Centre, both in Renfrew.

The Renfrew bridge features cable stays and pivots on slew bearings, with unequal cantilever lengths on either side of the pivot.

“The easiest swing span would be symmetric with forward and back lengths the same, a couple of steel girders and no cable stays,” says Phillips. “Adding the cable stays makes the structure more complicated in all of the analysis.”

The unusual design stems from the council’s brief to Scottish architect Tony Kettle to create a landmark structure. Transporting the two bridge leaves to site caused further design complexities.

Manufactured offsite in different locations outside the UK, the leaves were moved by various methods from yard to sea barge, which their design had to accommodate.

Had the concept design – created by Kettle, with engineers Sweco, Cass Hayward and KGAL – been executed, it would have been even more complex. But when the tenders came in over budget, client Renfrewshire Council asked its preferred contractor, Graham, to suggest some value engineering options to reduce the cost.

From about £100M for the concept design, changes to the design reduced the contract sum to £79.5M, although it has risen again as some of the removed elements – such as lighting – have been reintroduced. The project uses the NEC Option C target cost contract, allowing for pain or gain share in such matters.

Graham subcontracted the delivery of the bridge’s superstructure to Hollandia Iemants JV, which has employed H&H with Roughan & O’Donovan to execute the design.

Graham constructed the substructure of the bridge, employing Ramboll for the design, while Amey was subcontracted to Ramboll for the highway design.

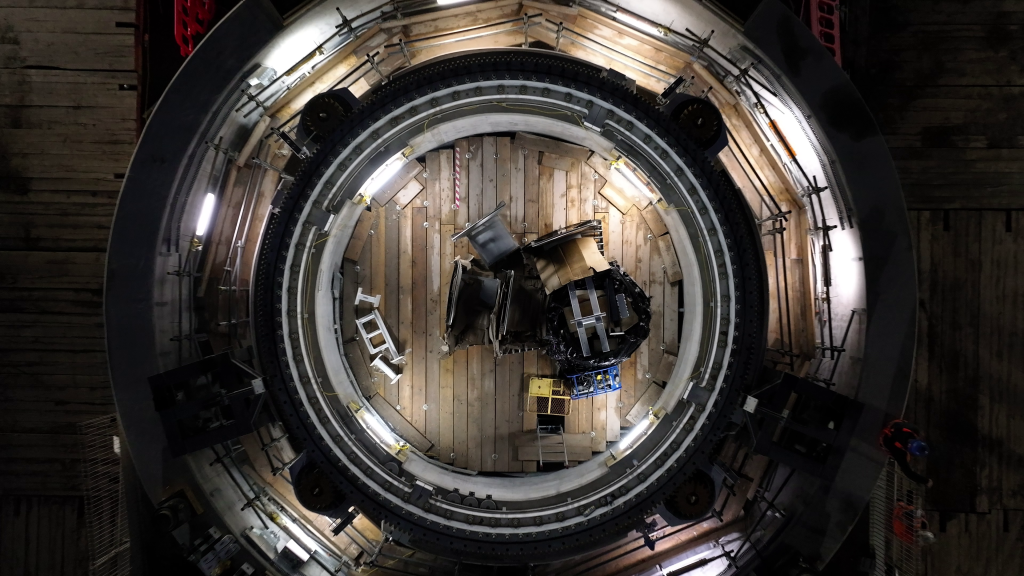

The two leaves, manufactured outside the UK, were towed down the river and transferred into place in spring

Simplified design

Kettle’s original design saw the pylons, centre joint and end joints all skewed to the centre line at 30°. The skews were a reference to the way the dry docks are cut into the riverbanks at angles.

“That would have meant there were four quadrants that are all unique,” says Phillips. “From a fabrication standpoint, that’s quite a bit of complexity.” Additionally, the cable stays were not balanced, with three on the back side of each of the four pylons and seven on the front side.

The final design sees the pylons set perpendicular to the bridge deck, with three cable stays on each side of the pylons and a radius rather than a skew at either end of the bridge to make the alignments easier. The designers simplified the cross-section of the steel bridge deck from a single orthotropic box section to a pair of box girders with a steel plate sitting between them, eliminating the steel that would have run along the bottom of the original section.

The width of the bridge deck slimmed down from 13.3m wide at concept to 11.3m wide at contract signature, although the council later asked that this be widened to 12.1m to provide space for a cycle way.

Further savings came from moving the pivot point. From a front span of 67m and a back one of 25m, H&H adjusted to 65m and 27m. “Although that’s only a two-metre shift in the pivot position, it helped reduce the overall mass of the bridge significantly and meant there was a much more efficient counterweight,” says Phillips.

With the bridge squared and balanced up, the designers still faced transportation issues. Iemants, in Hoboken, Belgium, used self-propelled module trailers (SPMTs) to move its leaf onto the sea barge.

Fellow steel fabricator Hollandia in Rotterdam picked its leaf up with three huge cranes due to the capacity of the retaining wall at the docks.

“This meant that we had to analyse different conditions for lifting the bridge, which also added a little bit of complexity,” Phillips says.

He enjoyed working through ways to optimise the design for both capital and operational costs. “You have t be very concerned about the long term maintenance costs,” he says.

“We put a lot of effort into balancing the loads on the slewing bearings. They are the key to the whole bridge and probably the most expensive single element. We worked hard to ensure we had no hot spots.”

A special detail was needed for the point where the two leaves meet, since each can vary in length by up to 90mm. The solution is a customised Maurer expansion joint, which can concertina in or out, using sensors and lasers to position itself.

Changes to the superstructure impacted Ramboll’s substructure design. “There was coordination with Ramboll, not just onto the superstructure but also at the critical interface at the rotating movable leaves and abutment, where you have to take traffic from the leaves onto the abutment,” says Paul van Hagen, who heads H&H’s London office.

The bridge features cable stays and pivots on slew bearings, with unequal cantilever lengths on either side of the pivot

In designing the piers and abutments, Ramboll’s aim was to minimise the moments in all the pile groups, says David Waterman, bridges and highways south director at Ramboll. “Because the bridge is rotating, you have to look at the pile groups when the bridge is in different degrees of rotation. There are quite a lot of load and geometric cases.”

The 1.2m-diameter bored, cast in-place concrete piles for the pivot piers and abutments vary in length, ranging from 30m to 44m, and pass through made ground, alluvium and glacial deposits to reach mudstone beneath. Ramboll used the 3D structural analysis package Plaxis to optimise pile layout.

The optimisation analysis cut a pile from each abutment, three from each pivot pier; there are 13 piles per pier and seven per abutment.

Ramboll reduced the concrete in the abutments by optimising the pile cap shape and making the bearing inspection gallery wider to reduce the volume of concrete.

Impressive manoeuvres

Despite the complexities of the structure, the biggest challenge for Graham was co-ordinating every construction activity with the many stakeholders involved, including the three local authorities, Marine Scotland, the Scottish Environment Protection Agency (Sepa), river authority Peel Ports and Glasgow Airport. Every move had to be explained and approved, considering impacts on river traffic, air traffic and migrating fish.

“It can take a long time to explain to people who don’t have a construction background how all the operations work,” says Graham contracts manager Jim Armour, born in Renfrew, who returned to his old primary school to tell the children there about the project.

Starting on site in May 2022, one of Graham’s first tasks was to check for unexploded munitions. The docks were bombed during the Second World War. There was remediation work on a shipyard area, had been a scrapyard over its long industrial lifetime.

“There was every bit of a car you could imagine in there,” says Armour. Sepa required a reduction in the metals content in the soil from 20% to 7%, which Graham had to verify by testing, before adding an anti-dig layer and topsoil.

Another early task was the diversion of the Yoker culvert, a Victorian brick structure. The alignment of the bridge meant the approach road would have run directly over the top of it, so the culvert was transferred 40m into a new, open channel.

Graham then installed sheet piles to create cofferdams in the river so the two pivot piers could be constructed. After that came concrete works for the pivot pier, plant room and abutment. Mechanical and electrical fit out started in February 2024.

Graham installed about 20 temporary piles on each side of the crossing for the temporary ramps to allow the transfer of the bridge leaves from barge to abutment. A further four piles were driven for a layby downstream to provide waiting space for river crafts.

Graham self-delivered the piling. “Marine piling is so high-risk and so expensive that there are very few subcontractors who would do it,” says Armour.

The most spectacular parts of the build came on two sunny days in April and May 2024, when the two leaves of the bridge were towed down the river and transferred into place using SPMTs via the temporary ramps.

The journeys down the river attracted attention, says Armour. However, few people were awake to witness the smooth transition of the leaves from the barges – since both took place at high tide, at about 2am.

The first operational closing of the Renfrew Bridge was executed on 24 July

Despite these manoeuvres, the most complex stage, according to Armour, was the commissioning. “We had to balance the bridge up on the cable stays, over the river, so we had to find a time where there is not a lot of river traffic to do it,” says Armour.

Graham successfully achieved the first operational closing of the Renfrew Bridge across the river on 24 July. The plan is to hand the bridge over to the council in autumn.

Armour attributes the successful execution of the works that have been undertaken so far to the collective competence of the team. He says: “There have been differences in opinion – mainly on how things should be done – but everybody’s goal was to get the bridge built and we are all working together to achieve that.”

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.

Responses