Fehmarnbelt | Casting of 73,000t concrete tunnel elements commences

This post was originally published on this site

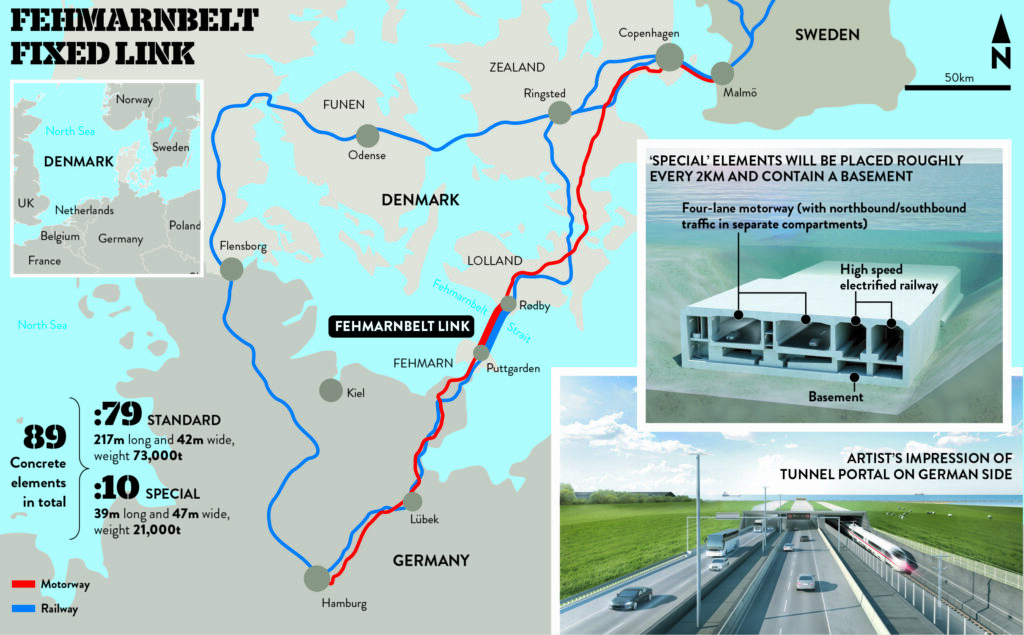

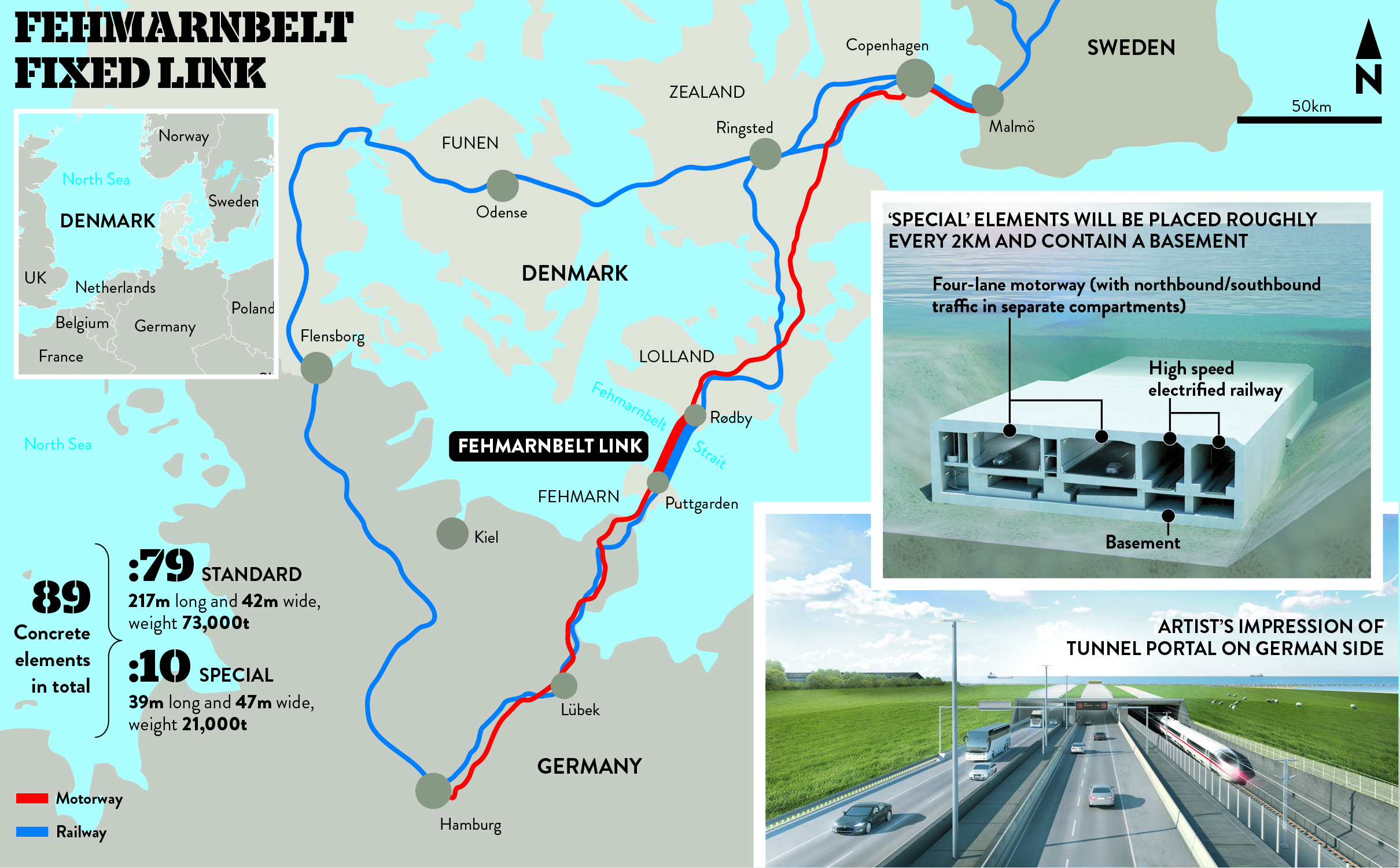

The first of more than 700 concrete segments that will eventually make up the Fehmarnbelt Fixed Link, the world’s longest immersed-tube tunnel, have been cast in Denmark.

Femern Link Contractors, the constortium delivering the 18km Fehmarnbelt Fixed Link, achieved the symbolic milestone at its factory on Lolland Island as the task of building the crossing continues to gather pace.

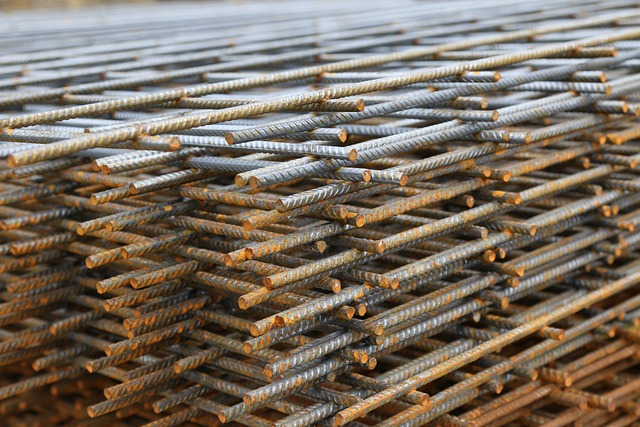

The scale of the job is immense. Of 89 tunnel elements, 79 are the same dimesnions at 217m long, 42m wide and 9m high, weighing roughly 73,000t. Each of these standard elements is produced from nine segments, the first of which has now been cast. Around 3,000m3 of concrete will be used per segment, meaning 27,000m3 per total element.

There will also be 10 “special” elements roughly every 2km along the tunnel that are 39m long and 47m wide, weighing 21,000t.

When completed towards the end of this decade, the £6bn tunnel will link Denmark with Germany, slashing up to two hours from journey times between the neighbouring countries. It will feature both a high-speed railway and a four-lane motorway.

Femern Link Contractors – a consortium of big names including Vinci, Bam International and Solétanche Bachy – is delivering the immersed tube, pre-casting and tunnel approaches.

“This is a very decisive moment and a major milestone in the Fehmarnbelt project,” said Jens Ole Kaslund, technical director at project promoter Femern A/S.

“The construction of the factory, the work harbour and the tunnel portal have been a major preoccupation but now we can unequivocally state that the casting of the elements for the Fehmarnbelt tunnel has begun – and that’s cause for celebration.”

Femern Link Contractors chief executive Sebastién Bliaut added: “Our preparations for the casting of the first segment have been very thorough, and it was vital that the team and the processes during the casting were optimally prepared to ensure that the casting proceeded as it should.”

The first tunnel element is expected to be immersed in the Fehmarnbelt next year. A trench is currently being dredged by a Dutch duo of Van Oord and Boskalis while a special vessel is being purpose-built in Poland to lay out a gravel bed.

Production of the tunnel elements will continue until 2027, with the crossing due to open in 2029.

Femern A/S is currently procuring for the £176.4M railway track and catenary systems construction contract. It is to be a “railway system of the highest standard” with an energy-efficient solution for traction power.

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.

Responses