Roads & Infrastructure Magazine

This post was originally published on this site

Fri, 18 Oct 2024 00:26:58 +0000en-AU

hourly

1 https://roadsonline.com.au/wp-content/uploads/2022/12/cropped-android-chrome-512×512-1-32×32.png

3232

Fri, 18 Oct 2024 00:26:58 +0000https://roadsonline.com.au/?p=46701

Four projects will share in $800,000 worth of funding to support trials and research of low-cost, cutting-edge safety technology for …

The post Level crossing projects to share in additional funding appeared first on Roads & Infrastructure Magazine.

]]>

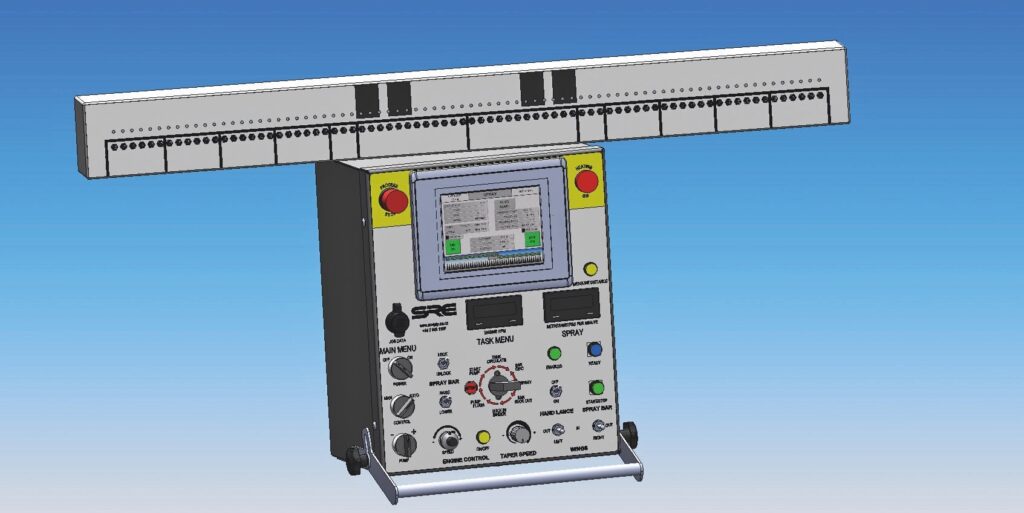

Four projects will share in $800,000 worth of funding to support trials and research of low-cost, cutting-edge safety technology for level crossings.

The funding is part of the second round of the Regional Australia Level Crossing Safety Program (RALCSP). Under the first round of the program, $2.8 million was distributed between six projects, which are already underway.

The trials and research will investigate human behaviours at level crossings, trial radar technology that detects upcoming obstacles, engage predictive models to identify high-risk level crossings, and use analytics tools to promote low cost and efficient upgrades.

The results will be used to inform ongoing activities under the National Level Crossing Safety Strategy currently being delivered jointly by the Federal Government, local governments, rail and heavy vehicle industry associations, and regulators.

Related stories:

Currently, most level crossings in regional Australia have either give way or stop signs, particularly where there is no reliable electricity source.

To address this, the $180.1 million RALCSP is also providing funding to deliver infrastructure upgrades such as rumble strips or boom gates, improve data, and promote safe behaviours around level crossings.

This is consistent with the National Road Safety Strategy 2021-30 which sets a goal for the Federal, state and territory governments of reducing road deaths by 50 per cent and serious injuries by 30 per cent by 2030.

To learn more about the RALCSP, click here.

The post Level crossing projects to share in additional funding appeared first on Roads & Infrastructure Magazine.

]]>

Thu, 17 Oct 2024 23:02:53 +0000https://roadsonline.com.au/?p=46698

A joint venture consisting of Jacobs and Seymour Whyte has been awarded an Engineering, Procurement, and Construction Management (EPCM) services …

The post Joint venture takes out Sydney Water EPCM contract appeared first on Roads & Infrastructure Magazine.

]]>

A joint venture consisting of Jacobs and Seymour Whyte has been awarded an Engineering, Procurement, and Construction Management (EPCM) services contract from Sydney Water, for works on the Upper South Creek Networks Program in Western Sydney.

The program will use an integrated delivery model to plan, procure, design, build and deliver resilient, affordable and sustainable wastewater services. It will ensure Sydney Water can continue to provide safe, reliable and affordable services to customers as the region continues to grow.

The Upper South Creek Networks Program is made up of five wastewater infrastructure projects across Thompsons Creek, South Creek, Badgerys Creek, Cosgroves Creek and Agribusiness and Lowes Creek.

Under the contract, the Jacobs Seymour Whyte Joint Venture will be responsible for delivering EPCM services, which include comprehensive program management, design, system planning, procurement, and integration throughout the project’s various phases.

The program will be delivered progressively across five project areas over a 12-year period. It’s projected that the program will deliver over 96 kilometres of wastewater pipelines, nine pumping stations, as well as supporting infrastructure like ventilation and maintenance holes/access.

The first stage of works will get underway before the end of the year, which will include the design and construction of new wastewater pumping stations and, gravity carriers.

Related stories:

These projects will help to improve the capacity of wastewater infrastructure for noteworthy facilities and locations in the region, such as the new Western Sydney International Airport, Bradfield City Centre and fast growing, surrounding suburbs.

Seymour Whyte Managing Director and Chief Executive Officer John Kirkwood said the joint venture brings together a wealth of experience in delivering large scale infrastructure projects.

“We are thrilled to be partnering with Sydney Water and Jacobs on this transformative project that will provide essential services to one of the fastest-growing regions in Australia,” he said.

Jacobs Senior Vice President Keith Lawson said the works program is a major step in the transformation and resilience of Sydney Water’s infrastructure systems

“By integrating our industry-leading design and program management experience with Seymour Whyte’s construction planning and management experience and Sydney Water’s system planning, understanding of future growth and system operational knowledge, we will help create a more secure future for the region,” Lawson said.

The post Joint venture takes out Sydney Water EPCM contract appeared first on Roads & Infrastructure Magazine.

]]>

Thu, 17 Oct 2024 22:03:59 +0000https://roadsonline.com.au/?p=46687

R&S Grating’s story and ongoing success can predominantly be attributed to the company’s commitment to family, and the legacy of …

The post Challenges and triumphs: The R&S story appeared first on Roads & Infrastructure Magazine.

]]>

R&S Grating’s story and ongoing success can predominantly be attributed to the company’s commitment to family, and the legacy of its past leaders. Tim Hockham and Steve Skinner reflect on the past and shed some light on the future.

Not many businesses across the roads and infrastructure sectors began their journey in a backyard stable. But then again, Road Safety Grating (R&S Grating) has always succeeded in doing things a little differently.

Back in 1974, a small backyard stable in Mentone, Melbourne was the backdrop for what would become one of Victoria’s oldest and leading supplier of high quality grates into Melbourne’s major road projects, and eventually a leading civil drainage supplier.

All of this kicked off when the late Stephen “Stevo” Hockham and his brother sought to establish a modest business, focused on the manufacture of welded steel grates.

As Steve Skinner, National Sales and Business Development Manager – R&S Grating explains, Stevo’s desire for success was a key factor in the company becoming a favoured grate supplier across Victoria for decades.

“To give you an idea of how things got started, someone came to Stevo one day and said ‘you should make grates’. That’s honestly where the business came from,” he says. “As Stevo would tell it, the story goes that he made the grate, the customer said it was the best he’d ever seen, and he asked if he could have another.

“I’m not sure if they even had a horse in the stable,” Skinner jokes. “It all started with Stevo. He was very passionate about grates. You think ‘how can you be passionate about grates?’ But he found a way, and that shone through in everything that he did.”

Skinner first joined the company over ten years ago, when R&S Grating was already an established and well-regarded manufacturer.

“I think the word got out that I wasn’t working for my old company, so Stevo approached me to come and work for him,” he says. “His pitch was as simple as ‘I want you to come and work for me’. It started with a phone call, I came into the office to see him, we had a great chat and he gave me two bottles of wine.

“I thought ‘that’s the first job interview I’ve ever done where I’ve walked away with two bottles of wine’. That was Stevo, he’d bend over backwards for anybody.”

Stevo was much more than just the Founder and patriarch of R&S Grating. He’s a life member of Municipal Works Australia, an organisation that he was heavily involved and committed to. He’s also highly regarded in the local community.

Skinner says there are plenty of stories when it comes to Stevo, with most providing some insight into his selfless and considerate nature. Hence his well-known nickname, the “Grate Man”.

“Years back, Stevo took a trip to the United States. He stayed up in a room that overlooked Niagara Falls. He thought it was one of the best things he’d ever seen. There were a few people at the business who were thinking of going on a holiday, so he said, ‘if you go over there, I’ll pay for your room to overlook the Niagara Falls, you have to see it’. He did that for a couple of people and the offer was there for everyone,” he says.

“He’d take generosity to another level, and he always looked up to other people in the business, not down. You had to do something seriously wrong to get on his bad side, I’m not even sure if he had one.”

Widely known for his humour, humility and generosity towards R&S Grating’s customers – as well as the wider community – Stevo’s passion and determination endure through his three sons, all now working in the business, including his eldest son, Tim.

For Tim Hockham, R&S Grating was always a part of his life growing up.

“My earliest memories of the company are coming to work with Dad in the 1990s, I would’ve been about 12 at the time,” he says. “In those days, Dad would bring Pop along as well to help out. The company was much smaller then.

“There’s a lot of things that have changed since those days.”

A constant theme throughout the years has been a strong connection to family, as well as the past. As Hockham explains, he’s one of many employees who have a strong family connection to the business.

“It’s not just about my family and I think that’s what sets us apart. All our employees and their families really care. Everyone wants the business to do well, everyone wants each other to succeed. We really care about each other and that generational factor plays a big part in that,” he says.

Taking over the mantle from his father, Hockham is among the company’s leaders who are helping to settle the ship, with enduring market challenges not making life easy for the R&S Grating team.

The most important thing is that the team has each other, he says.

“The family element has been in this business since it started. It’s not just our family, there are many multi-generational family relationships across the business.”

Malifa Taeleipu, Production – R&S Grating, started coming to R&S Grating in 2006, helping his father Sam.

Taeleipu says the strong family values of R&S Grating are reflected in his family’s close ties to the business, with his father working at the grate manufacturer for more than 20 years. Taeleipu himself is coming up on 18 years of service.

“I was originally a labourer, cutting steel for my father to fabricate. I didn’t know it at the time, but he took me under his wing and taught me about the real world. He’s taught me everything that I know today, and I grew to appreciate those opportunities to have lunch with Dad and spend time with him,” he says.

These experiences have been instrumental throughout his journey at R&S Grating. He adds that the support of Stevo, Hockham and Skinner, helps to create a positive workspace where integrity and honesty help to drive further product improvements.

“Stevo was always so supportive of my father and myself, he was a big part of not only work, but also my upbringing and the life lessons I learned along the way,” Taeleipu says. “The apple doesn’t fall far from the tree with Tim. His understanding and care for everyone here speaks volumes of where he and the company are heading.”

Related stories:

Pushing forward

While 2024 has come with its challenges, the year has also marked a year of celebration for R&S Grating. The company is celebrating 50 years of manufacturing in Australia.

From its beginnings in the backyard stable, R&S Grating has grown to be successful and competitive on major government contracts, helping to maintain the safety and structural integrity of grates on Melbourne’s major connections, such as the Bolte Bridge, Tullamarine Freeway (Citylink), the M80 Ring Road and the new West Gate Tunnel Project, to name just a few.

A key part of the company’s growth was the innovative Weaved Sump Grates, regarded as its signature product.

Such was the innovation and popularity of the Weaved Sump Grate that R&S Grating’s initial concept was subsequently re-created by competitors in the market.

“At the time we weren’t getting a lot of freeway work, even though we had the best product for freeways. We had one of our weave grates tested and we discovered that the grate had exceptional load sharing capabilities. After a report was conducted, we learnt that the uplift was greater than the downforce,” Skinner says.

“Effectively we were building a bridge, so we needed to have bridge-inspired technology in our grates if we wanted them to last. That’s where the extra bolt down came from. Plenty of our weave grates are still in many places in Melbourne, some have been there for 25-30 years. And these are connections that are trafficked by up to 100,000 motorists daily.”

R&S Grating’s weaved grates continue to be a popular solution. Hockham says it’s the versatility that’s added to the design’s longevity.

“We introduced the weaved grate in 1992, which coincided with the introduction of Australian Standards for access covers and grates,” he says. “Councils might’ve had their own requirements and standards, but there was nothing on a national level.”

The weave grate was among the first to provide a bike safe grate, with most grate manufacturers at the time going for a traditional design. The way it’s welded makes it a very strong grate and more efficient by enabling the load bars to be at larger gaps, meaning less steel is involved in manufacture.

“Suddenly you had a very strong grate that was efficient, lighter and cheaper to produce, while also being bike safe. It was a big innovation that a lot of councils jumped on,” Hockham says.

“We look to continually innovate. We have an unwritten policy not to stagnate anywhere. We’re always looking at improving our products and optimising them to keep us competitive. That happens right across the board.”

This spirit of innovation lead to another success story for the company, with the development of its SMC Ecolite range of light-weight composite pit lids.

“We introduced a composite lid range around 15 years ago now,” Hockham says. “There were options available in the market, but these were made from a timber core, coated in fibreglass and were prone to damage and structural collapse. We introduced the first full-depth composite pit lid into the market and worked hard to engineer it to be the lightest and strongest available. The hard work paid off and we’re now the leading supplier of composite pit lids in Victoria.”

For Skinner, it’s product consistency that continues to put R&S Grating in the box seat for upcoming contracts and opportunities.

“It’s extremely rare that one of our products fails. Occasionally we might lose a contract, then six to 12 months later, the contractor will come knocking at our doors asking if we can replace it,” he says.

“There’s been some horror stories where cheaper grates have been installed that don’t meet specifications and aren’t as safe as products made in Australia. R&S Grating has always had a reputation for quality, but it can be challenging when cheaper imports enter the market.

“At the end of the day, our grates work, and they’ve worked for years. The quality of our grates is the statement that we make to the sector. You put our product down, then you don’t need to worry about it again for years to come.”

Leaving a legacy

When it comes to the future, Hockham says maintaining and improving R&S Grating’s product range is at the top of the priority list. So is continuing the strong platform for success that his father built.

“Dad was very proud to see one of his products in the ground. I just want to keep seeing our grates on important infrastructure. Seeing the R&S Grating name around Melbourne, as well as the growth of our team, is what fills me with the most pride,” Hockham says.

“Just the fact that we can have such a presence is amazing and it’s something that my family and many other families have been working on for five decades.”

He says, R&S Grating isn’t perfect, sure, but the drive of its team to eradicate imperfections is what’s helping to elevate its products and services from others in a competitive market.

“We don’t want anyone to remember R&S from our mistakes. We want to be remembered for what we did about those mistakes,” Skinner says.

“Even if it’s not our mistake, we approach each case in the same way. That’s who we are as a business.”

This article was originally published in the October edition of our magazine. To read the magazine, click here.

The post Challenges and triumphs: The R&S story appeared first on Roads & Infrastructure Magazine.

]]>

Thu, 17 Oct 2024 20:55:44 +0000https://roadsonline.com.au/?p=46682

In a world where sustainability is at the forefront of corporate concern, industries are proactively exploring the potential to substitute …

The post SAMI: As pure as it gets appeared first on Roads & Infrastructure Magazine.

]]>

In a world where sustainability is at the forefront of corporate concern, industries are proactively exploring the potential to substitute a portion of their products with sustainable alternatives. As Hamidreza Sahebzamani, PHD, MIEAUST, Technical Services Manager – SAMI Bitumen technologies writes.

Often, alternative materials are derived from waste or by-products. The primary objective of using these alternatives is to meet one or more of the following targets: enhancing technical properties, reducing carbon emissions, supporting the circular economy, improving sustainability targets, and cutting costs.

Some of these alternatives can be utilised directly without any modifications, while others necessitate additional processing to ensure safety, or to enhance their properties.

As the global drive to reduce carbon emissions and non-renewable resource usage gains momentum, it can create potential doubts. This transition may open the way for the usage of materials that have yet to be proven safe and of effective performance.

Regarding the road industry, we must bear in mind that the most sustainable road is the one that lasts the longest. There is no advantage in constructing a road with a lower initial carbon footprint but a reduced lifespan when compared to traditional ones. The carbon cost of maintaining or prematurely reconstructing pavements may negate the initial gain of low carbon footprint if the pavement doesn’t have the same longevity.

Consequently, the whole of life carbon footprint would be higher. It is also necessary to consider the rolling resistance of roads. Notably, a road that is not smooth can generate additional emissions from cars and trucks that may exceed the carbon footprint of the road’s entire construction.

WEO and REOB

Lubricating oils derived from petroleum are used in a variety of applications, ranging from the lubrication and protection of engine parts to heat and power transfers. Over time, depending on their application and operating environment, these oils become contaminated or otherwise degraded, resulting in what is known as Waste Engine Oil (WEO).

Despite its contamination and apparent dirtiness, WEO never becomes entirely unusable. In fact, WEO is recyclable and can be re-refined back into lubricating oils. The re-refining process employs distillation and hydrotreating. WEO is dehydrated under atmospheric pressure to remove water and light hydrocarbons.

Atmospheric distillation then separates the reusable lubricating oil from the heavy oil. Vacuum distillation further separates the reusable lubricating oil into re-refinable base oil and a non-distillable residue, known as REOB or Vacuum Tower Asphalt Extender (VTAE).

The re-refinable base oil is further processed into re-refined base oil stocks, ready to be used in the production of new lubricating oil.

Re-refined Engine Oil Bottom (REOB) or Vacuum Tower Asphalt Extender (VTAE), are the non-distillable residue from the WEO refining process.

Any re-refined products derived from used oil that do not meet this definition should not be referred to as REOB/VTAE, and the degree of their usage in asphalt production remains uncertain.

REOB comprises approximately 12 per cent of the total WEO composition.

It consists of higher boiling components, typically containing paraffinic lubrication oil, residual additives, and engine wear metals.

REOB can contain as much as 60 per cent residual lubricating oil, about four per cent polymer, and various soluble metals, which account for about five per cent of the total REOB composition1. Figure 1 shows the process of re-refining used oil and where the REOB/VTAE is produced.

Safety

Used oils (WEO) can contain Polycyclic Aromatic Compounds (PACs), with some of these compounds classified as carcinogenic. During the processing of used oil in a vacuum tower refining system, PACs are typically removed from the residuum (bottoms). REOB/VTAE materials have been found to contain only trace levels of PACs.

Concerns have been raised about the PAC content in REOB/VTAE due to potentially carcinogenic levels in used oil. To investigate this concern, the Asphalt Institute conducted research, collecting seven samples at different stages of the re-refining process and testing them for mutagenicity index (MI) and PAC levels which are measures of carcinogenicity of a chemical substance.

Samples taken before vacuum distillation exhibited high levels of MI and PACs, indicating a higher risk of carcinogenicity; however, these levels were significantly reduced in samples taken after the vacuum distillation process2.

Currently, REOB/VTAE is not recognised as a carcinogen, although ongoing research is exploring more on this.

This highlights the importance of suppliers clearly declaring the contents of bitumen when they use any stream of re-refined used oils.

Related stories:

Technical performance

In the United States, some State Departments of Transportation (State DOTs) have raised concerns about pavement durability and may restrict the use of REOB. A review of State DOT specifications conducted in 2022 revealed that five State DOTs permit the usage or limited use of REOB. Among these, there was no consistent maximum usage limit; one State DOT allows up to 5.0 percent, while another permits a maximum of 8.0 percent. The remaining three State DOTs impose no limits. Additionally, thirty-one State DOTs have no stated restrictions, with two requiring prior approval for potential use, and fourteen State DOTs do not allow the use of REOB1.

Research on pavement performance impacts has yielded conflicting conclusions. There is limited information regarding the comparative field performance of mixtures made with binders containing REOB/VTAE versus those without.

Some studies suggest that REOB/VTAE adversely affects the aging characteristics of bituminous binders, consequently reducing the cracking resistance of in-service pavements. In contrast, other researches indicate that asphalt mixtures blended with REOB/VTAE perform equally well or better than those made with neat bitumen of comparable stiffness.

The literature is inconsistent, with some authors asserting that REOB/VTAE is innocuous, while others warn of potential detrimental effects on performance. Furthermore, data indicate that the performance of binders and mixtures containing REOB/VTAE depends on the dosage, the source of REOB/VTAE, and the source of the bitumen. [1, 2, 3, 4, 5, 6, 7, 8]

Numerous studies suggest that current binder specifications require improvement to accommodate REOB use, such as extending Pressure Aging vessel (PAV) aging to better characterize all types of modified binders. X-Ray Fluorescence (XRF) technology has been identified as a qualitative tool for detecting the presence of REOB/VTAE in bitumen.

A recurring theme in the research highlights the significant impact of aging on the relaxation properties of mixtures and binders. Extended PAV aging (greater than 20 hours) may be necessary to distinguish performance differences in binders that age variably.

The addition of recycled asphalt pavement (RAP) tends to make ΔTC more negative, as these materials are significantly aged in the field. Additives containing paraffinic base oils, when combined with REOB/VTAE, have been shown to accelerate the rate and extent of m-control in a binder (leading to a more negative ΔTC). The presence of REOB/VTAE can adversely affect binder relaxation properties as it ages.

The Asphalt Institute has recommended further exploration of the binder parameter ΔTC after 40 hours of PAV as a more effective method for characterizing long-term binder durability and performance (over five years)2. However, recent research suggests that this parameter may not be a reliable indicator for polymer-modified binders.

Studies have also shown that even trace amounts of REOB in bitumen can render it unsuitable for producing emulsion. Over the past two years, some incidents have occurred regarding the quality of bitumen emulsion in the Australian pavement industry.

Internal research by SAMI indicated that the base binder used for these emulsions contained trace metal elements typically found in REOB products, underscoring the importance of responsible usage of these additives and transparent declarations.

Detection

It is not possible to directly identify or quantify the exact content of REOB in bitumen. However, because bitumen does not naturally contain certain elements found in REOB, one can reasonably infer that the presence of these elements in bitumen suggests the potential inclusion of REOB.

Several instrumental analytical techniques are available for determining and quantifying these elements. These methods include graphite furnace atomic absorption (AA) spectroscopy, inductively coupled plasma spectroscopy (ICP), energy dispersive X-ray fluorescence spectroscopy (EDXRF), and wavelength dispersive X-ray fluorescence spectrometry (WDXRF)1.

The EDXRF method is versatile, capable of analysing various matrices, including solids, liquids, and powders. It typically covers an elemental range from sodium to uranium on the periodic table, with concentrations ranging from sub-parts per million (ppm) to 100 percent.

Elements with higher atomic numbers generally have better detection limits than lighter elements with lower atomic numbers. In EDXRF, X-rays produced by a source, such as an X-ray tube, irradiate the sample.

The elements in the sample emit fluorescent X-ray radiation with discrete energies characteristic of those elements. By measuring the energies of the emitted radiation, one can identify which elements are present (qualitative analysis). Additionally, by measuring the intensities of these emitted energies, it is possible to quantify the amount of each element present in the sample (quantitative analysis)1.

Responsible use

REOB/VTAE has been utilised in the bitumen industry for several years and is currently gaining increased attention due to sustainability targets and the push for cost optimization within corporations.

The use of this type of additive should be approached with caution and responsibility, ensuring clear communication with customers. There are several inconsistencies regarding the performance of asphalt and bitumen, particularly with emulsions made using these additives.

Additionally, certain streams in the re-refining process of waste engine oil have been shown to pose safety risks. It is essential for governmental regulations to be established to ensure transparency in these practices.

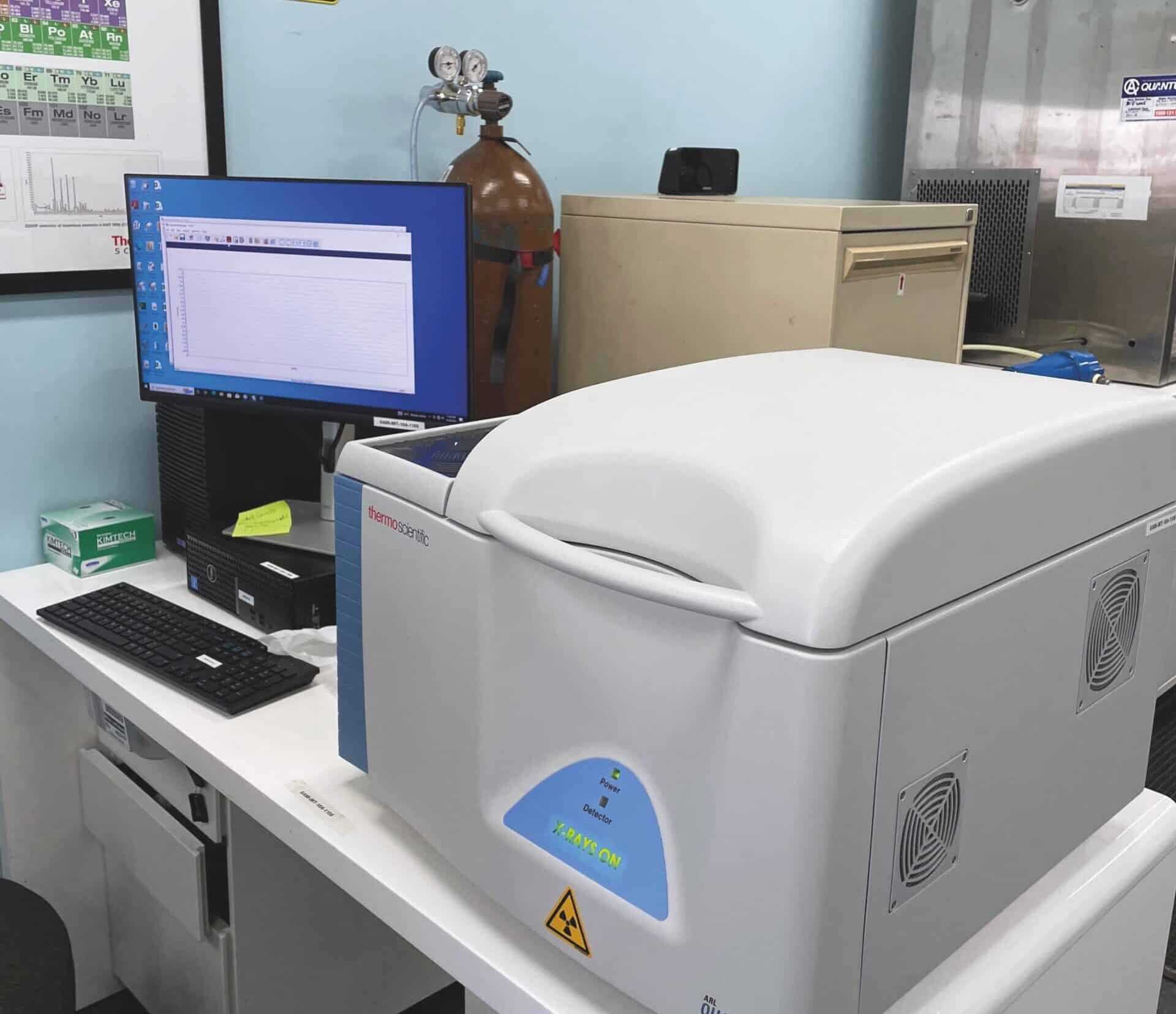

It is also crucial for users of bitumen to have a full understanding of the materials they are working with. At SAMI, we are committed to this principle and have recently set up an EDXRF device in our central laboratory in Camellia, NSW.

This device can detect trace elements in bitumen samples, enabling us to identify any unknown materials.

This technology and process are available to serve all stakeholders in the pavement industry, ensuring that binder users and producers can be confident that the product they are using is genuine and meets their specifications. This will decrease the risk of reduced quality and problems in production, especially with emulsions.

Reference: 1. Responsible use of re-refined engine oil bottoms (REOB) in asphalt binder, 2023, FHWA 2. State of the knowledge – The use of REOB/VTAE in asphalt – IS-235, 2016, Asphalt Institute 3. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% RAP mixtures, Martins Zaumanis, Rajib B. Mallick, Robert Frank, TRB 2013 4. The performance of aged asphalt materials rejuvenated with waste engine oil, Christopher D DeDene, Zhanping You, IJPE 2014 5. Five year performance review of a northern Ontario pavement trial: Validation of Ontario’s double-edge-notched tension test (DENT) and extended bending beam rheometer (BBR), S.A.M. Hesp, S.N. Genin, D. Scafe, H.F. Shurvell, S. Subramani, CTAA, 2009 6. Asphalt cement loss tangent as surrogate performance indicator for control of thermal cracking, Abdolrasoul Soleimani, Shanon Walsh, Simon A. M. Hesp, TRR, 2009 7. Effect of waste engine oil residue on quality and durability of SHRP Materials Reference Library Binders, Kelli-Anne N. Johnson, Simon A. M. Hesp, TRR, 2014 8. Cold winter and early asphalt pavement cracking observed in Ontario, Ludomir Uzarowski, Gary McDonald, John Rizoo, Gary Moore, Vimy Henderson, CTAA, 2015

This article was originally published in the October edition of our magazine. To read the magazine, click here.

The post SAMI: As pure as it gets appeared first on Roads & Infrastructure Magazine.

]]>

Thu, 17 Oct 2024 02:07:31 +0000https://roadsonline.com.au/?p=46670

Several communities across Victoria will share in a $1.5 million investment through the Flexible Local Transport Solutions Program (FLTSP) to …

The post Transport programs boosting local communities appeared first on Roads & Infrastructure Magazine.

]]>

Several communities across Victoria will share in a $1.5 million investment through the Flexible Local Transport Solutions Program (FLTSP) to deliver small scale transport projects.

The investment will support 16 community led projects, including RMIT University researchers who will use a $100,000 grant from the FLTSP to develop a modelling tool to assist with decision making to deliver cycling infrastructure projects across regional Victoria and fast track the development of cycling networks.

A $30,000 grant from the FLTSP will help the City of Greater Bendigo analyse transport options to reduce emissions and car dependency, while $60,000 has been allocated to fund a Strategic Transport Assessment that will define the future transport needs of the Ballarat region.

Mansfield Autism Statewide Services has received support to purchase a 12-seater bus, to deliver bus services for students traveling between Benalla and Wangaratta – so that they can attend TAFE courses outside of current timetabled bus services.

Related stories:

Not for profit group, South Port Day Links (SPDL), received a $45,000 grant to update their transport booking system – benefiting caregivers and people living with a disability that use the service to access vital health, recreational and educational services.

The FLTSP also holds a strong focus on inclusion and is supporting a pilot program in Wodonga that is helping up to 28 migrants and Aboriginal and Torres Strait Islanders receive their driver’s license.

The program will also focus on upgrading a number of pedestrian footpaths across regional Victoria. While cyclists will receive better connections to regional public transport, with more bike racks to be installed on bus services across Warrnambool, Portland, Mildura, Bairnsdale and the Latrobe Valley.

Gabrielle Williams, Minister for Public and Active Transport said the government was proud to be part of these initiatives across the state.

She said by providing evidence-based solutions and helping communities be more connected, the government was delivering a more modern, efficient and reliable transport system that gets passengers where they need to go.”

For more information, vic.gov.au/local-transport-victoria.

The post Transport programs boosting local communities appeared first on Roads & Infrastructure Magazine.

]]>

Thu, 17 Oct 2024 02:05:10 +0000https://roadsonline.com.au/?p=46667

The $1.162 billion Federal and Queensland government-funded Gympie Bypass has opened to traffic, cutting travel times, improving motorist safety, and …

The post Gympie Bypass opens to traffic appeared first on Roads & Infrastructure Magazine.

]]>

The $1.162 billion Federal and Queensland government-funded Gympie Bypass has opened to traffic, cutting travel times, improving motorist safety, and access and flood immunity.

The project has included construction of a new 26-kilometres, four-lane divided highway between the existing Bruce Highway interchange at Woondum, just south of Gympie, and Curra in Queensland.

It includes three new interchanges – at Flood Road, Gympie Connection Road and Curra as well as 42 new bridges at 23 locations.

Motorists will still be able to access Gympie from the Old Bruce Highway via the interchange at Woondum and from Curra in the north.

It is the final section of a 62-kilometre Bruce Highway program of works between Cooroy and Curra, totalling $2.549 billion.

Construction of the overall Cooroy to Curra program began in September 2009.

Related stories:

While major construction for the bypass is finished, there will be some intermittent works over the next few weeks while the crew finishes some minor activities on the connections at either end of the new highway.

Anthony Chisholm, Minister for Assistant Minister for Regional Development and Senator for Queensland said the opening has been a long time coming.

“Gympie residents and regular visitors to this popular part of Queensland will be thrilled to hear that the bypass is ready to use,” he says.

“Today’s opening is the culmination of 15 years’ worth of construction on this 62-kilometre upgrade to the Bruce Highway, which will improve safety, flood resilience and is designed to meet the transport needs of the Gympie, Maryborough and Sunshine Coast communities well into the future.”

For more information, www.tmr.qld.gov.au/cooroytocurra

The post Gympie Bypass opens to traffic appeared first on Roads & Infrastructure Magazine.

]]>

Wed, 16 Oct 2024 00:47:06 +0000https://roadsonline.com.au/?p=46661

The Australian Flexible Pavement Association’s National Worker on Foot Awareness Course is the sector’s opportunity to invest in the safety …

The post Enhancing safety around mobile plant and equipment appeared first on Roads & Infrastructure Magazine.

]]>

The Australian Flexible Pavement Association’s National Worker on Foot Awareness Course is the sector’s opportunity to invest in the safety and well-being of its workforce, reducing risk and potentially saving lives.

Across the road construction and maintenance sector, safety is not just a priority – it’s a foundational commitment, particularly when working in close proximity to mobile plant and equipment. Recent data highlights the critical need for enhanced safety measures and training for workers on foot near these powerful machines.

To address these concerns, AfPA (the Australian Flexible Pavement Association) has introduced the National Worker on Foot Awareness online course, a specialised program that exemplifies AfPA’s unwavering dedication to improving safety protocols and ensuring a secure work environment for all individuals on site.

The demand for improved safety training is underscored by statistics from Safe Work Australia, revealing a concerning pattern: mobile plant and equipment are disproportionately involved in hazardous incidents on construction sites.

In the 2021-22 financial year, 3840 serious claims were linked to mobile plant machinery, including 10 fatalities.

These figures demonstrate the necessity for targeted, high-quality safety training and effective protocols tailored to the risks associated with mobile plant operations. This course meets that need head-on.

Mobile plant machinery is integral to road construction and maintenance projects, including equipment such as excavators, graders, profilers, pavers, and rollers.

The size, movement, and operational complexity of these machines introduce substantial risks for workers on foot.

The congested and dynamic nature of construction sites further amplifies these risks, posing challenges in visibility and communication between workers and machinery operators.

AfPA’s course addresses these challenges directly, equipping participants with the knowledge and skills needed to prevent accidents and ensure smooth operations.

Workers on foot are particularly vulnerable to accidents such as being struck by moving machinery, run over, or injured by falling objects.

Given the dynamic nature of construction sites, it is imperative for workers to be well-versed in safety protocols and to remain vigilant about their surroundings.

The National Worker on Foot Awareness Course is an opportunity to invest in the safety and well-being of a workforce, reducing risk and potentially saving lives.

The Primary goal of the course is incident prevention. It includes strategies for establishing safe zones around mobile plant machinery, conducting regular safety checks, and implementing site-specific safety protocols.

Related stories:

Additionally, participants will learn effective response techniques for emergencies, equipping them to react promptly and appropriately in the event of an incident. These critical skills could be the difference between a near-miss and a serious injury.

Importantly, the course also provides industry specific content, giving a detailed understanding of mobile plant machinery commonly used in road construction and maintenance.

Participants will gain insights into machine movements, associated hazards, and best practices for mitigating these risks.

This foundational knowledge is essential for accident prevention and fostering a safer work environment.

By enrolling, you are ensuring your team is equipped with the latest industry knowledge to stay safe and productive.

The last focus is effective communication strategies, with communication being crucial for site safety.

The course emphasises Positive Communication (PosCom), training participants on using communication tools and techniques to ensure awareness of each other’s movements among all site personnel.

This is not just training – it’s a strategy for success in high-risk environments.

Whether you’re a small contractor or a large organisation, this course adapts to your needs, offering unparalleled value and effectiveness to suit multiple requirements.

Enrolling in this course demonstrates a proactive commitment to risk management and safety for employers and workers alike.

Given the significant risks associated with working near mobile plant machinery, The National Worker on Foot Awareness Course by AfPA offers an indispensable solution for addressing these risks and elevating safety standards on construction sites.

The National Worker on Foot Awareness course is planned to roll out online by the end of October.

Keep an eye on the AfPA social channels for updates.

This article was originally published in the October edition of our magazine. To read the magazine, click here.

The post Enhancing safety around mobile plant and equipment appeared first on Roads & Infrastructure Magazine.

]]>

Tue, 15 Oct 2024 22:17:28 +0000https://roadsonline.com.au/?p=46655

In Queensland, the Department of Transport and Main Roads (TMR) has awarded Seymour Whyte, in a joint venture with John …

The post Contract secured for Beerburrum to Nambour Rail Upgrade appeared first on Roads & Infrastructure Magazine.

]]>

In Queensland, the Department of Transport and Main Roads (TMR) has awarded Seymour Whyte, in a joint venture with John Holland, the contract to deliver stage one of the Beerburrum to Nambour (B2N) Rail Upgrade project.

The project will include the duplication of the rail line between Beerburrum and Beerwah and the straightening of the rail line between Beerburrum and Glass House Mountains.

As well as an upgraded park ’n’ ride facility at Beerburrum, new or upgraded road overpasses and upgraded train signalling systems.

B2N Stage one now advances to its next phase under a Collaborative Project Delivery Agreement between the Department and the John Holland Seymour Whyte Joint Venture.

This contract award allows the joint venture with its designers SMEC Australia and WSP Australia to continue to finalise the designs and start construction of the major works package.

Related stories:

The joint venture brings experience to the project, having been appointed in 2023 to undertake preconstruction and design work as part of an Early Contractor Involvement (ECI) process.

This included collaborating with TMR and Queensland Rail in design development, stakeholder engagement, site investigations and site preparation activities, and environmental and cultural heritage planning and approvals.

Preliminary designs will be further refined, shared with the community and finalised, with construction, testing and commissioning activities delivered in a staged sequence of packages over the next three years.

The B2N Rail Upgrade will increase the capacity and reliability of the North Coast Line, enabling more efficient travel and improved passenger and freight connections between the Sunshine Coast, Moreton Bay and Brisbane.

This upgrade plays an important role in broader transport planning for an enhanced and integrated public transport network that better connects Sunshine Coast communities.

B2N Stage one ties in with the Direct Sunshine Coast Rail Line at Beerwah and is among the projects being planned together to improve public transport services and infrastructure for the growing South East Queensland region.

For more information, visit: https://www.tmr.qld.gov.au/

The post Contract secured for Beerburrum to Nambour Rail Upgrade appeared first on Roads & Infrastructure Magazine.

]]>

Tue, 15 Oct 2024 05:21:41 +0000https://roadsonline.com.au/?p=46652

Material provided by CONQA With over 30 years experience and an enduring commitment to quality, Premier Services Group is a …

The post How Premier Services Group work on Queen’s Wharf Brisbane set a new standard in digital QA excellence with CONQA appeared first on Roads & Infrastructure Magazine.

]]>

Material provided by CONQA

With over 30 years experience and an enduring commitment to quality, Premier Services Group is a leading specialist building services contractor in the Australian construction industry.

Investing in innovative construction technology has been an important part of improving their workflow as they continue to work on large, complex projects such as Queen’s Wharf Brisbane being built by Multiplex.

Regarding Quality Assurance (QA), the industry’s mechanism for preventing costly defects and documenting compliance, their Project Manager Troy Turney says completing paper-based ITPs (Inspection & Test Plans) “was nearly a person’s full time job to manage and look after that especially on a job of this scale.” Moving to a digital QA platform, “CONQA has simplified that, bringing it into the new age,” he says.

Related stories:

The Premier Services Group team kindly welcomed us on site and showed us how they’ve integrated CONQA into their day-to-day process. Their understanding of QA’s value for their business as they grow, and the way they’ve engaged their team in learning the platform is fantastic- we’re proud to be working with them.

Hear from Troy Turner (Project Manager), David Perry (Sprinkler Lead Hand / Site Foreman) and Keenan Dytor (Project Manager) in this video.

The post How Premier Services Group work on Queen’s Wharf Brisbane set a new standard in digital QA excellence with CONQA appeared first on Roads & Infrastructure Magazine.

]]>

Mon, 14 Oct 2024 22:47:17 +0000https://roadsonline.com.au/?p=46649

Works have wrapped up on the $81 million upgrade of Thomas Road, south of Perth, with both heavy and regular …

The post Upgrades complete for Thomas Road appeared first on Roads & Infrastructure Magazine.

]]>

Works have wrapped up on the $81 million upgrade of Thomas Road, south of Perth, with both heavy and regular vehicle drivers benefitting from smoother and safer journeys along the connection.

The large volume of heavy vehicles and other through traffic travelling to and from the South West and Wheatbelt regions necessitated these works, with more than 19,000 vehicles passing through intersections in the area daily.

Starting in early 2022, the program of works have delivered a range of improvements, including a dual carriageway between Kwinana Freeway and Bombay Boulevard; construction of a roundabout at Bombay Boulevard and a four-metre-wide pedestrian and cyclist path with lighting, as well as the construction of a dual lane roundabout at Thomas Road and Nicholson Road and upgrades on approach to the intersection.

Works also saw the construction of a dual lane roundabout at Thomas Road and Kargotich Road; additional street lighting between Bombay Boulevard and Kargotich Road; and added safety measures including shoulder widening, new line markings, raised reflectors and resurfacing.

Related stories:

The final package of works involved the construction of new two-lane roundabouts at the intersections of Nicholson and Kargotich Road.

Further upgrades are planned for the road through the Tonkin Highway Extension, which is expected to commence construction next year.

Western Australia Transport Minister Rita Saffioti said the works would help to improve the safety and efficiency of the “critical route” for freight and the local community.

“The safety upgrades have included additional lanes, more street lighting and roundabouts – all of which will provide a safer and smoother journey for road users,” she said.

“These upgrades will improve traffic flow and reduce congestion while making it safer for heavy vehicles, including oversize, over-mass loads, to traverse this key freight route.”

The post Upgrades complete for Thomas Road appeared first on Roads & Infrastructure Magazine.

]]>

Responses